The Engineer Development Program was implemented in order to enable graduates from different engineering branches to gain significant knowledge in a short time, thanks to a multidisciplinary training program.

%2FAA-27814404.jpg)

In the first phase of the program, which aims to shorten the adaptation period by bringing the participants closer to the company culture, it is aimed to develop engineering knowledge in the field of aviation. Then, the young people, whose responsibilities are determined by considering their fields of work, attend the theoretical and applied trainings in the fields of structural, flight sciences, avionics and software in the second phase. Participants in the third phase carry out project studies to carry out a task determined in line with the competencies they have acquired throughout the process.

TAI Academy President Prof. Dr. Ahmet Pınarbaşı said that during the employment process, young engineers were trained very well in terms of theory, but they found that they needed practice in the fields of aviation and space industry.

Pınarbaşı stated that they started a program called the Engineering Development Program based on this need, and said:

"As far as we know, this is a unique program implemented for the first time in Turkey. We employ our newly graduated engineers and they are recruited into the program in groups of 40-50 people. Our friends from different fields such as machinery, materials, electrical-electronics and aviation take 4-5 months. We both give quick trainings, introduce the aerospace industry and teach how to design an airplane in a short time. We have 3D printers in our workshop. We have the aircraft they designed produced and then they fly in real conditions. Thus, they graduate and find themselves in a plane, helicopter, space, etc. We send them to the units where they will work.”

%2FAA-27814406.jpg)

Stating that they received very positive feedback from the field regarding the program, Pınarbaşı stated that the young engineers went to the unit ready to work at the end of the program. Pınarbaşı said, "Our friends learn about TUSAŞ, the industry, how design and production are done in a short period of 4-5 months. We received very positive feedback and the program continues successfully." said.

"They solve problems much faster"

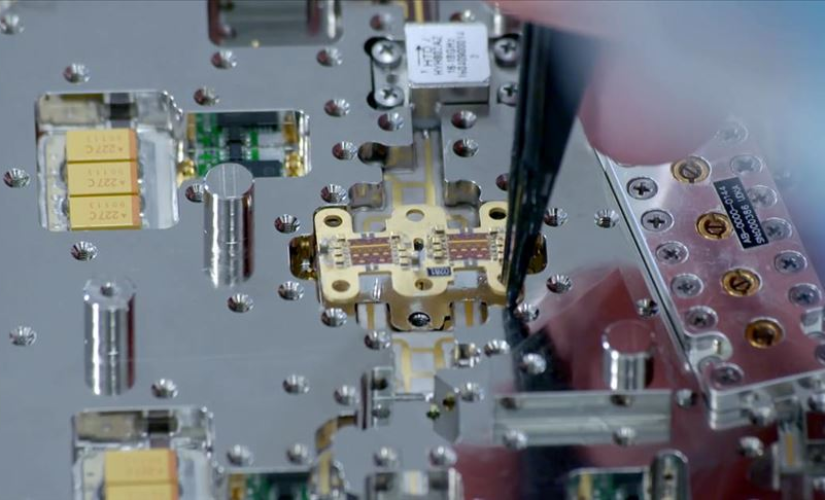

Engineer Development Program Chief Görkem Şimşek stated that the participants went through a 2-month general training process within the scope of the program, and that the production processes of an aircraft were experienced during the workshop phase.

Explaining that they are working on elements such as the architecture, equipment and equipment suitable for the task of the aircraft to be produced during the production process, Şimşek noted that at the end of the 4th month, the aircraft was assembled, and then ground and flight tests were carried out.

Şimşek stated that the engineers received feedback from the units where they worked at certain intervals, and said, "We receive very good feedback from the units and our friends. They are working together for the first time with different disciplines. They socialize professionally and socially, this is very useful inside. The feedback we receive from their managers, "I can say that the graduates of the program solve the problem very quickly compared to a new engineer. I can say that we are achieving what we want to do." used the phrases.

%2FAA-27814413.jpg)

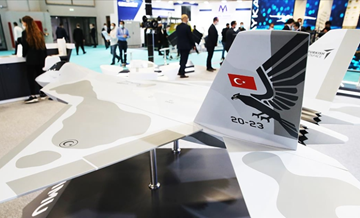

Nuri Demirağ's design came to life

Ozan Ege Camcı, one of the participants of the Engineer Development Program, said that he worked in the flight sciences unit of the MGP-7 Group within the scope of the program.

Emphasizing that they have successfully completed the program and that they will be distributed to the relevant units, Camcı said:

"We participated in a program that included all the construction processes of an airplane from start to finish. It was a very detailed program, from concept design to the placement of avionics parts and weight calculations. All the processes seen in the construction of a real airplane are seen here and we are involved in it. We also apply all kinds of methods to be applied in the design, We do research and analysis of them. Problems arise, we solve them. In the end, we try to create a successful project. When you are doing a project at school, you choose your project team from your friends, you are suddenly among 50 people here and you don't know anyone. A very comprehensive project should emerge. We practiced what we knew, but it was a new situation for all of us to come up with a project with 50 people coming together. This was the biggest contribution to us."

Stating that they designed a vehicle close to the twin-engine aircraft that Nuri Demirağ, one of the iconic names of Turkish aviation, could not design and manufacture, said, "We designed it on a load-release mission. Since Nuri Demirağ's plane was designed to be a fighter plane, we wanted it to be a performance vehicle." he said.

AA